|

PINS BACK CO., LTD.

|

Custom Cloisonne Hard Enamel Lapel Pins

| Price: | 0.2~0.5 USD |

| Payment Terms: | T/T,L/C,D/A,D/P,WU;paypal |

| Place of Origin: | Guangdong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Cloisonne Hard Enamel Lapel Pins

Betterfly Clutch On Back

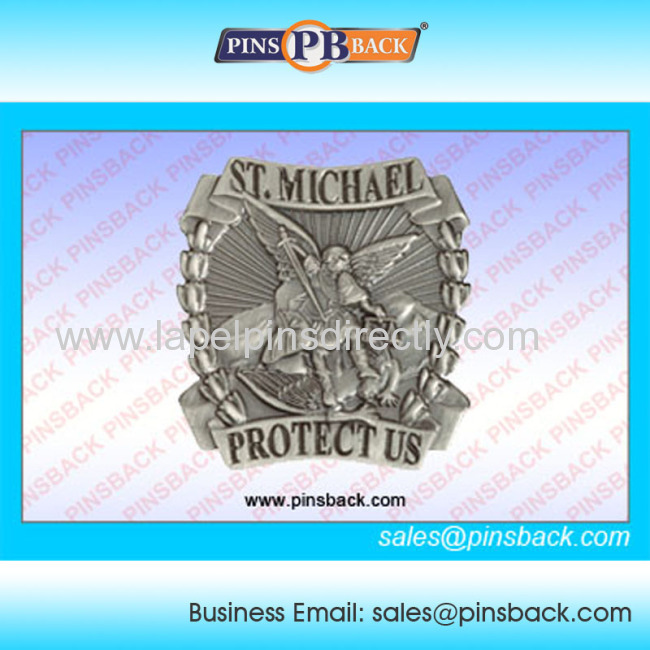

Silver Plated Finish

MOQ : 100PCS Afford Price

Paypal ,Western union , T/T

Cloisonne Hard Enamel Lapel Pins

The difference between hard enamel and soft enamel pins?

Hard enamel is a die struck pin with enamel, or a painted fill. Once the enamel is applied, the pin is heated to a high temperature, allowing it to harden. Once hardened, it receives a glossy polish, ensuring that the paint and metal borders are smooth to the touch.

Hard enamel pins date back more than 20 years, when the cloisonné process was invented. While cloisonné's colors are limited to 120, the benefit of hard enamel is that it can highlight more than 1,000 different pantone colors. The colors do not blend and are very distinct. Hard enamel pins are less expensive to produce and have a rapid turnaround time.

Hard enamel pins are very high end and jewelry-like in appearance and quality. Typically more expensive to produce than soft enamel pins, hard enamel are the highest quality lapel pins, and by far the most durable. With highly durable properties, it ensures that hard enamel pins can withstand the test of time. Perfect for specialized logos, these high-quality pins will not disappointment customers.

Soft enamel lapel pins are the least expensive and the most popular pins on the market. Soft enamel is also a die struck pin with an enamel fill. Instead of being heat treated, the paint air-dries which causes slight settling. This creates a unique, multi-dimensional look because the paint is at a lower level than the metal borders. Instead of feeling smooth, the pin has textured ridges.

Soft enamel pins are still excellent in quality, but are more flexible for customers' needs and budgets. Typically used for schools, promotional items, trading pins, sports memorabilia, organizations and nonprofit groups, soft enamel pins make up nearly 70% of pin production.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Cloisonne Enamel Pins

Custom Lapel Pins

Die Struck Lapel Pins

Photo Etched Lapel Pins

Enamel Lapel Pin

Soft Enamel Pins

More>>